Manufacturers have listed poor electricity, multiple taxations, high-interest rates, and poor accessibility to ports as parts of challenges affecting the operational capacity of companies in Nigeria.

This is according to a quarterly Manufacturers CEOs Confidence Index (MCCI), conducted by the Manufacturers Association of Nigeria (MAN) to measure the pulse of the manufacturing sector.

The survey which captured the First Quarter of 2019, had over 200 Chief Executive Officers (CEOs) of MAN member-companies across the six geo-political zones of the country and the ten Sectoral Groups of the Association, respond to questionnaires in a bid to identify key areas that need review.

READ ALSO: SEC Approves MTN’s 20.35bn Ordinary Shares On NSE

The result from the first quarter survey showed that manufacturing stood at 51.3 points, slightly above the minimum 50 points threshold of good performance.

This implies that the Manufacturing sector is still struggling as operators have a seemingly low confidence level but a high expectation that manufacturing performance will improve.

On Capital Expenditure, the majority of respondents did not agree that Government implementation encouraged productivity in the sector.

The Association affirmed the survey by highlighting the available poor economic infrastructure such as inadequate power supply, bad road network, high cost of abstracting water, low patronage and many more.

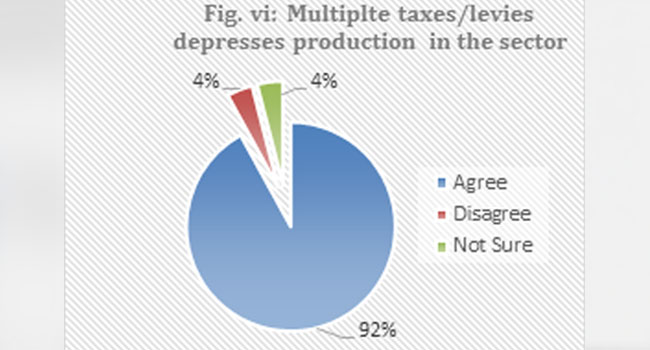

Meanwhile, 92 percent of the CEOs interviewed, agreed that multiple taxes and levies depress production in the manufacturing sector.

They also agreed that poor access to national ports and the associated gridlock negatively affects productivity in the manufacturing sector.

Although, 44 percent of respondents, agreed that the level of local sourcing of raw-materials has improved in the manufacturing sector. While 37 percent disagreed, and the remaining 19 percent were not sure if local sourcing of raw-materials has improved in the sector.

Effect of Executive Order 003 was also examined and 40 percent disagreed that patronage of Nigeria manufactured products has improved based on the order which mandated all Government establishments to make Nigerian manufactured goods first choice in their procurement processes.

The manufacturers recommended that the Government must make conscious efforts to repair and expand the roads leading to Lagos Ports, make other ports outside Lagos, functional so as to address the gridlock challenges and the associated cost.

They also asked that Forex should be made available for the purchase of manufacturing inputs and there should be a continuous improvement on the power supply and the general upgrade of the nation’s infrastructure.

The survey highlighted that the Capital Expenditure component of the National budget should be conscientiously implemented to bridge the infrastructure gap in the country.